When you have finished your scale beauty, often the finishing touch is fitting a flybarless head with either 2 or maybe lots more blades. Setting these up is essentially the same no matter how many blades there are. The first thing we need to think about is the linkage. Hopefully the manufacturer of the head/model will have given you measurements of the links from the swashplate to the blade. If not, have a guess and make up a link. In either case. make up only one link for now and work on one blade. Then when one is correct you can make up the rest.

The swashplate driver is a device to lock the center of the swashplate in position relative to the mast. It allows the swashplate to rise and fall but not twist. When you first fit this, you can put it in an infinite number of positions and as you move it, the pitch on the blades will alter. Hence, the exact length of the link is best determined when the timing is done. The timing is a function of an effect called precession which means that any input given to the disk, will happen 90 degrees later. However this only happens when the disk is nearly upto speed and how it knows that, is something I have yet to work out.

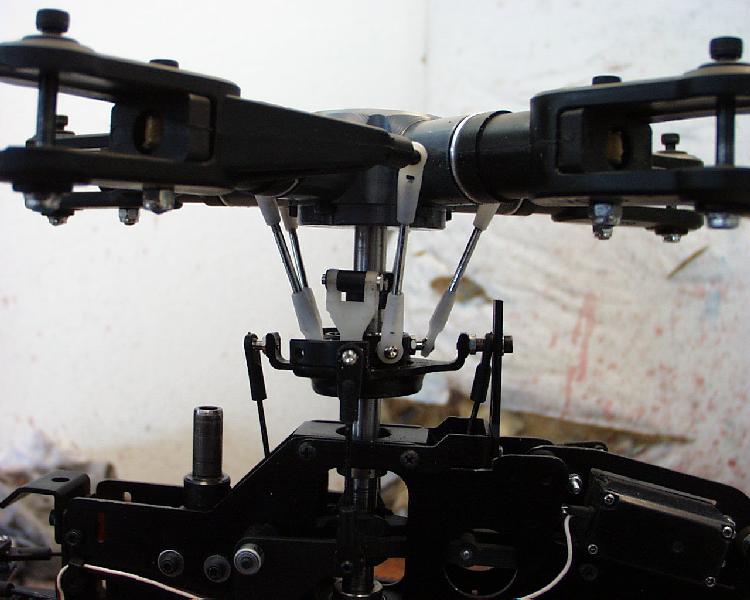

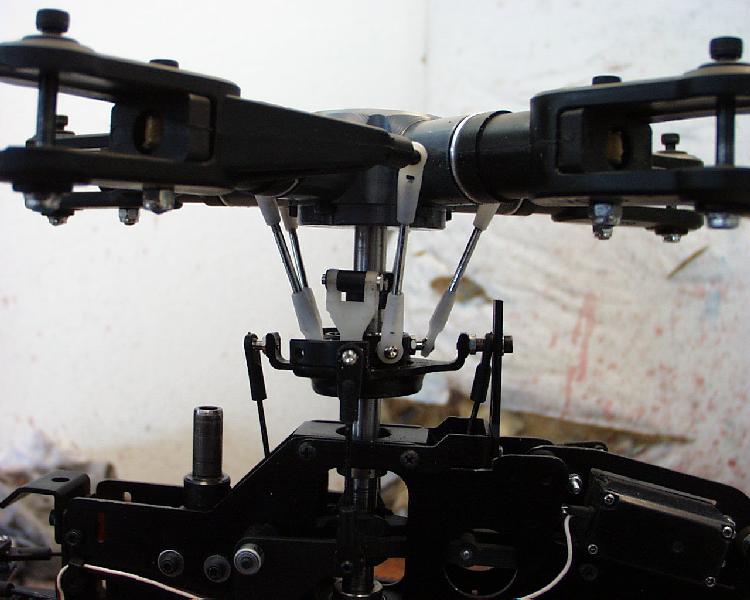

This is the 5 blade head I fitted to Xcell mechanics for my Seaking. Note the pushrods are straight and hefty. Setup your multiblade head so that the pushrod is straight and temporarily tighten the driver set screw. Now move the blade so it is over the tailboom. Switch on the radio and move the AILERON. I suggest for setting up you put in lots of expo on the aileron and elevator to ensure there is no inadvertent interaction. At least 75% should do it. Now, as you move the AILERON control. the blade pitch should alter. If you move the ELEVATOR control, the blade should remain still. Turn the driver until you obtain this and snug it down again. If the pushrod is not vertical and you have the ability to adjust the swashplate timing via your radio, now is the time to do this. I am familiar with the JR PCM10X and it has timing as one of the options under swashplate, but the range of timing is limited. Adjust the system mechanically and electronically so that there is no interaction between elevator and aileron and the pushrod is as near vertical as possible.

This was written many years ago and I have now progressed through several radios. The actual transmitter is unimportant today as most multiblade setups are controlled by a head gyro such as a V-bar or Bavarian demon. They have the phasing function built in and when using one of these devices, the basic setup remains the same, get the pushrods vertical. Now you adjust the phasing in the head gyro as above, but leave the swashlock in a fixed position so that the swash can move up and down without binding through the whole range of travel.

On the subject of head gyros, I am often asked which is the best. Manufacturers are constantly striving to keep one step ahead of the competition and to sell you the latest technology. The answer is, whichever one you like. I have tried several and settled on the V-bar. I liked it as you could buy a small programming unit to use in the field without needing a computer. The latest unit from Mikado, the V-bar manufacturer, is called the Neo and it does not support the programmer so you need your laptop. Many have had good results with the Beast X as it uses potentiometers to adjust the various parameters. Others favor the Naza H and Skookum SK 720 as it can be fitted with a GPS system which will stabilize the helicopter if you let go of the sticks.

Multiblade tail rotor setups are much simpler as they require no setting up, but if you are going to more than 3 blades you may need to reduce the blade size in order to keep the control system in balance.

This brings us to the consideration of which blades to use. Vario insists that its Bendix heads be used with special blades which have the Center of Gravity well forward. In most fiberglass and carbon fiber blades, the weight is a strip of lead placed right along the leading edge of the blade so it cant get any further forward than that. Wooden blades have slots milled them to accept the weights and they may be a little further back from the leading edge. I strongly recommend you use Fiberglass or carbon blades on any scale machine. Wooden ones simply aren't consistent enough.

When it comes to flying a flybarless head, you need to be aware that as you spool the head up and move the cyclic, the disk will not move as you expect. It may move in another direction all together and then corkscrew around to the correct place. Don't worry, this should happen until the head is at flying speed, but be aware. If you move the cyclic during spool up, the disk will continue to tilt and you must keep moving it to get the disk horizontal again. Its just like a heading hold tail gyro which will drift until the heli can move then it will correct, but with the head gyro, the heli may tip over so it's best to leave the sticks alone until therotor is up to speed and then take off firmly. Just before takeoff, everything should be stabilised and now, if you tip the disk forwards it should go forwards. When you have familiarised yourself with the hover and are into forward flight, don't forget to control the height with the collective. My biggest error is trying to control the height with the elevator and of course when I do this the heli flies faster and climbs even more. Fly slowly at first until you get used to it, but fly it often or you will never become familiar with it and it will always be a bit intimidating.